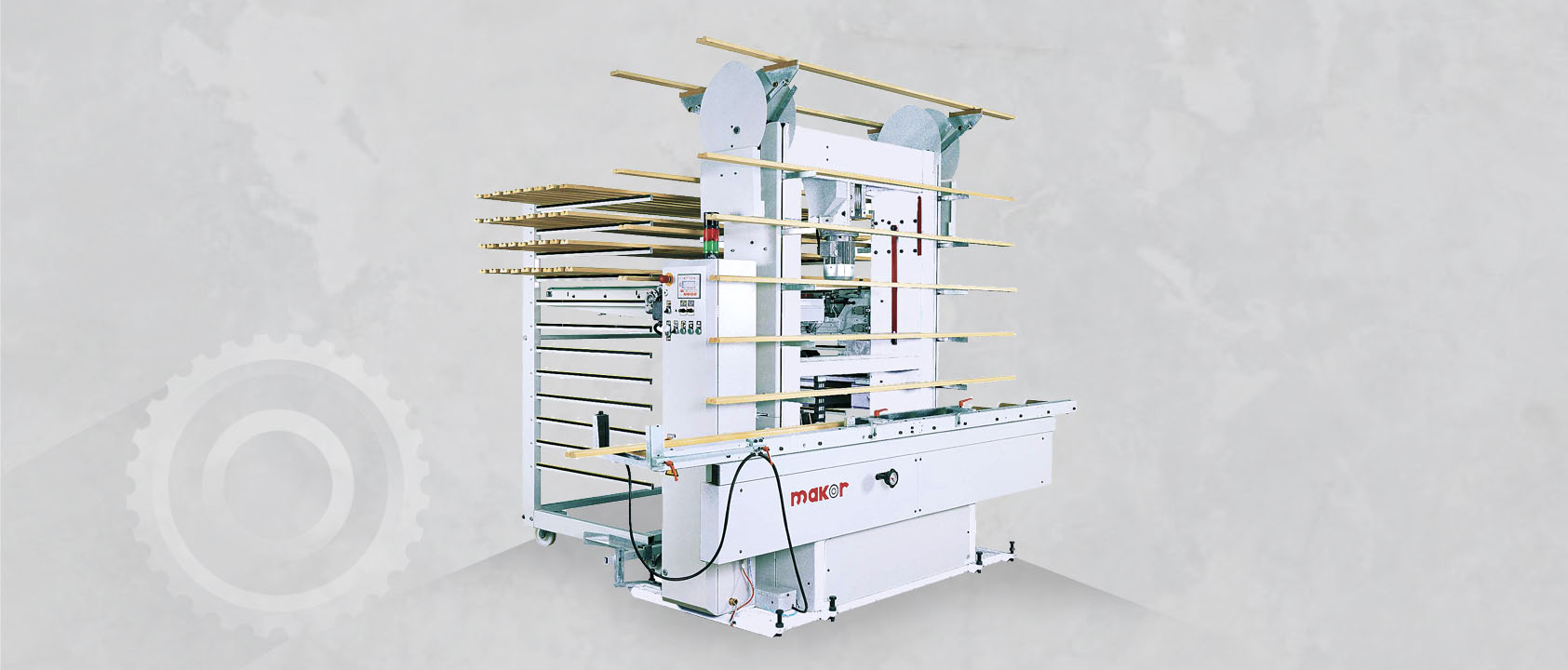

Designed for the transfer of linear mouldings, picture frames and profiles coming from the drying trolleys to the automatic working lines. The pieces are moved only with the support of the lower part in such a way that the treated surfaces are not touching any mechanical part, allowing a perfect finishing quality.

Realised in electro-welded steel. N° 2 – columns that are part of the machine base, necessary for a stable and firm support of the moulding withdrawing. Taking of pieces by track arms, transport by feeding roller conveyor with continuous adjustable speed through inverter. Operating panel with liquid Crystal display .

Programmed for 5 languages.

Fast and reliable

Extremely compact

For profiles of length from 1800 to 300 mm and width up to 180 mm.

Motorisation controlled by a powerful PLC and inverter for the smooth movement of profiles.