19 – 22 March 2024

NUREMBERG

Hall 3 Stand 3-449

The world-leading trade show for windows, doors and facades

FREE PASS – Code FF24MAKOR

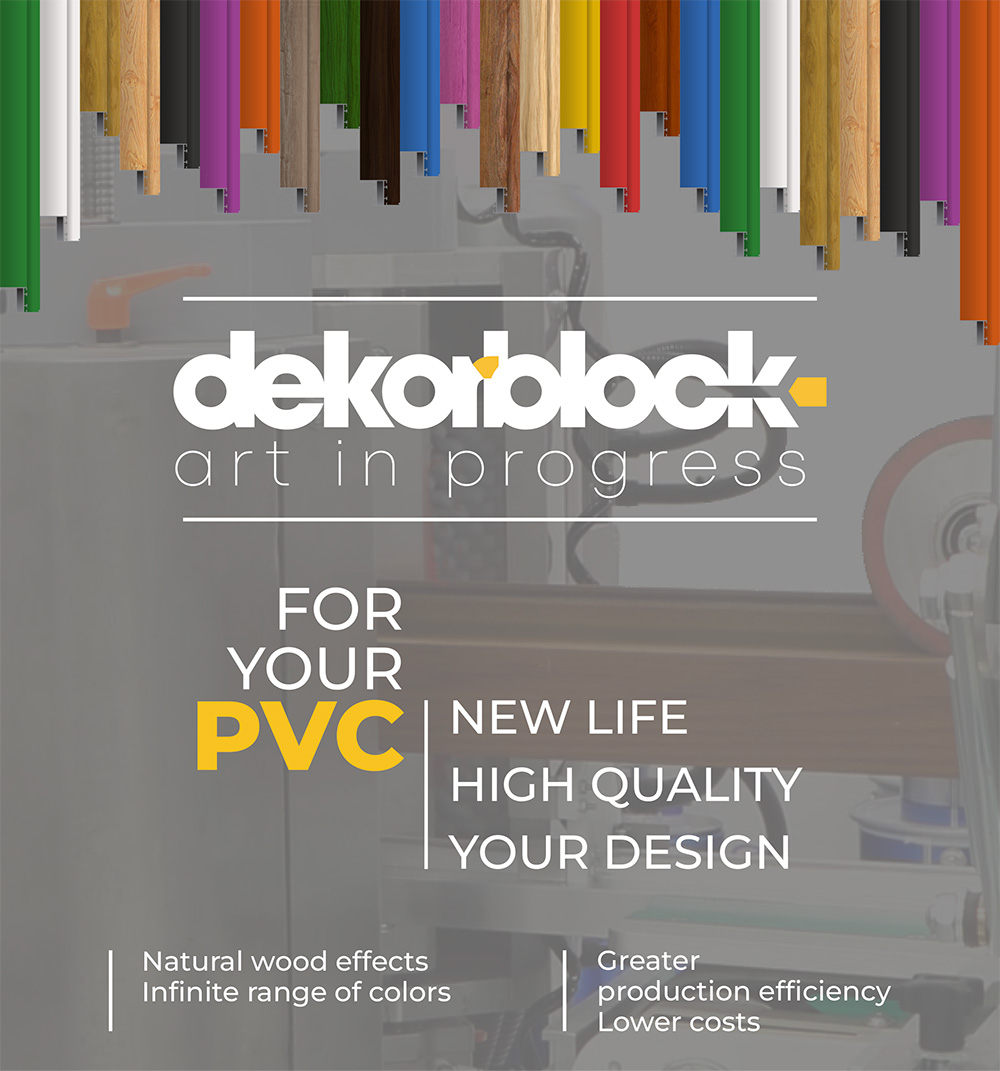

Siamo gli specialisti del finishing, leader di settore da 50 anni.

L’Italia è la nostra casa, il mondo la nostra meta.

Dal 1968 concepiamo, creiamo e vendiamo tecnologia. Dal piccolo artigiano alla grande industria, dal legno al vetro, dalla plastica al metallo, noi garantiamo soluzioni.

Catalogo generale

Sfoglia il catalogo direttamente online.

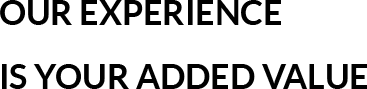

Advanced solutions

for Industry 4.0

Technologies 4thefuture

La piattaforma Tapio

e l’innovazione Makor

nell’industria 4.0

Rimani aggiornato

[wysija_form id=”1″]

Tutti i nostri Webinar

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

-

Loggati per vedere il video

- Oltre 25mila macchine prodotte

- Presenti in 5 continenti

- 3 test lab attivi (Italia, China, Usa)

- Più di 200 prove fatte ogni anno