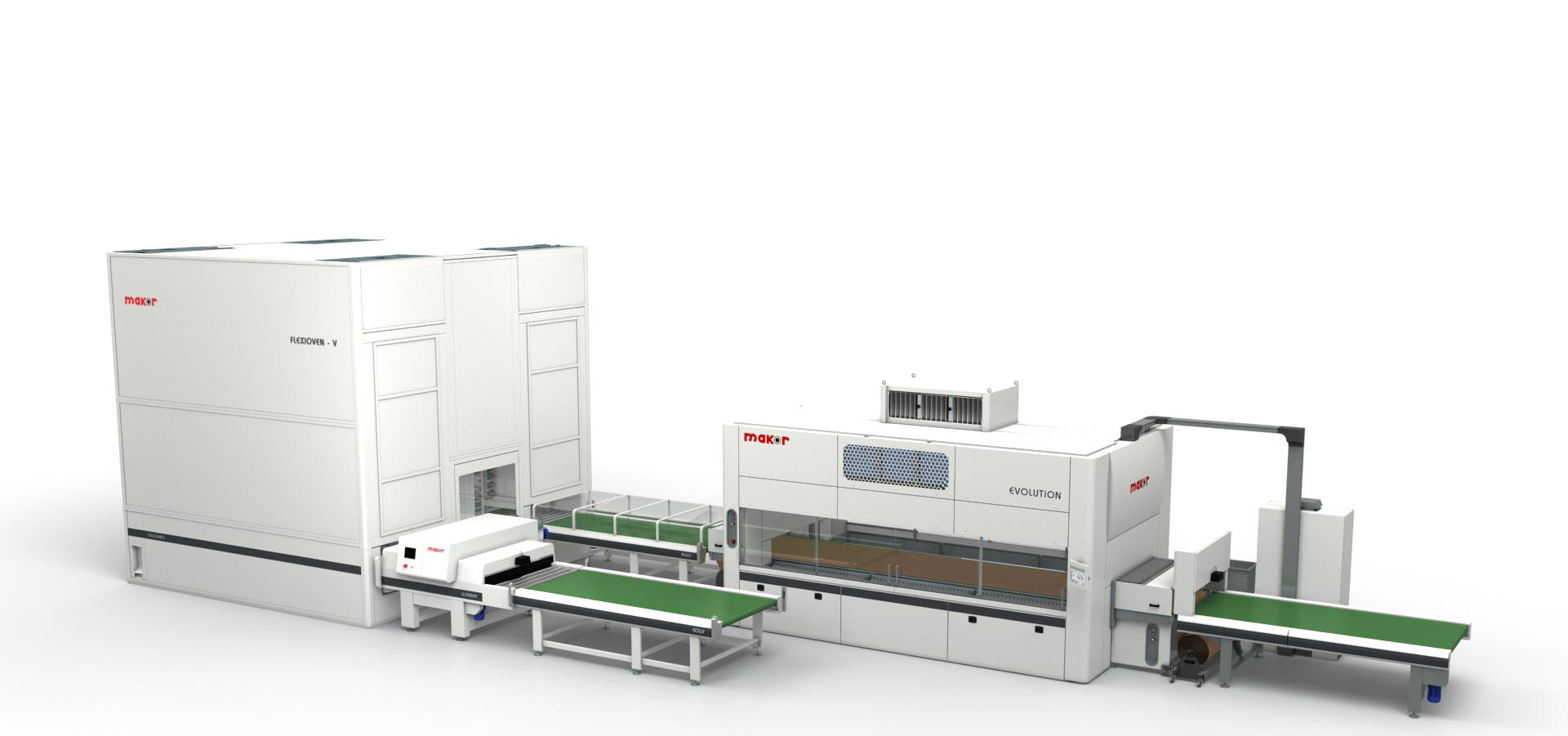

08 Feb Flexi Oven, a new flexible oven by Makor

Flexible system of the drying level, it can be set level-by-level. flexibility in the management just like a real storage.

For flexible drying both of different drying time and for pieces of different height.

For flexible oven of small capability (just in-time) or combined oven-storage of big capability (high production and just in-time)

MODELS AND FUNCTIONING MODE

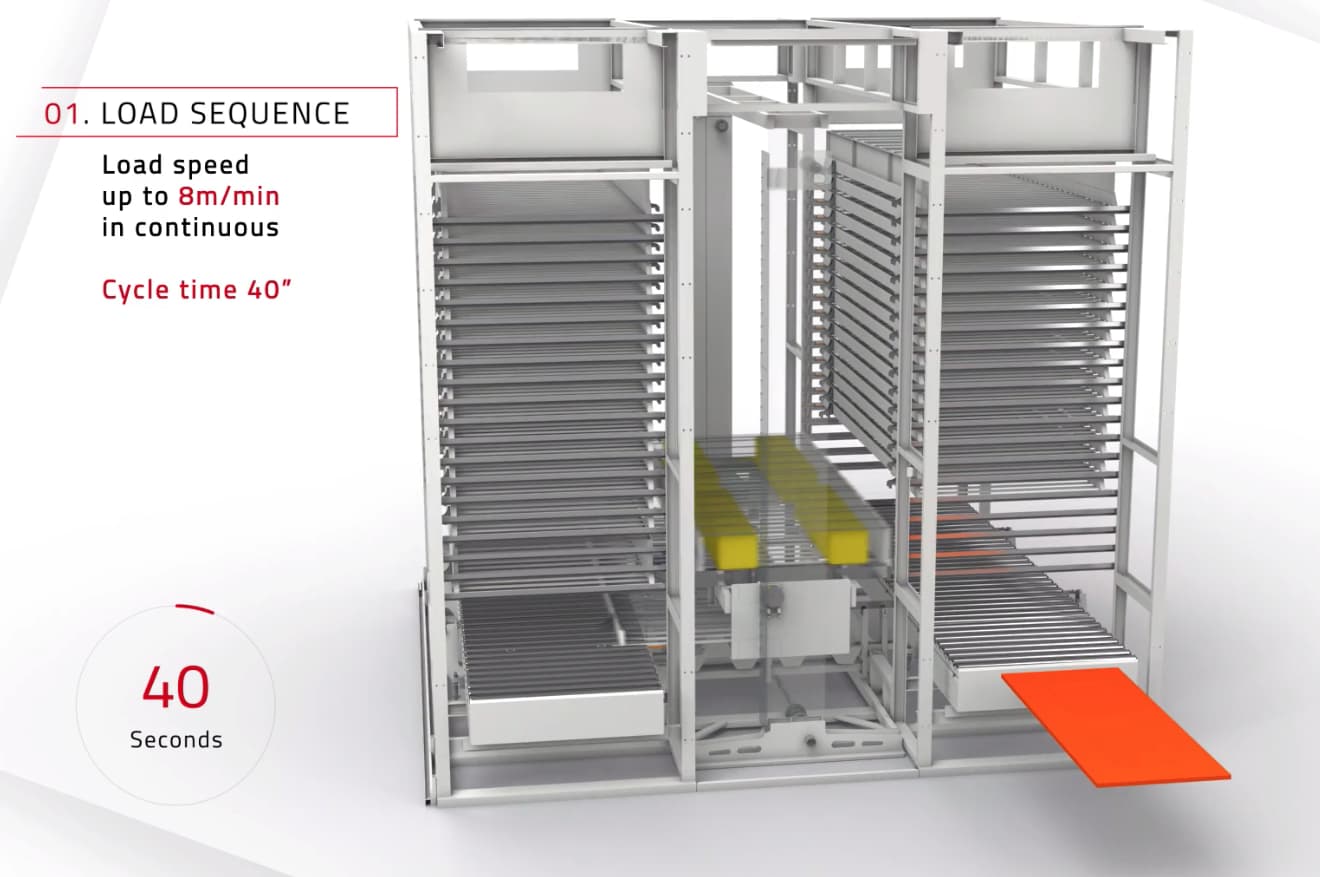

The tray moves with the pieces inside:

- total cover of the tray for quality finisning, glossy included.

- Possibility to select the dwelling time (even aifferent for every tray).

- Cycle time equal to 40 sec, that in the version vith 5.5m tray allows feeding in continuous up to 8 m/min.

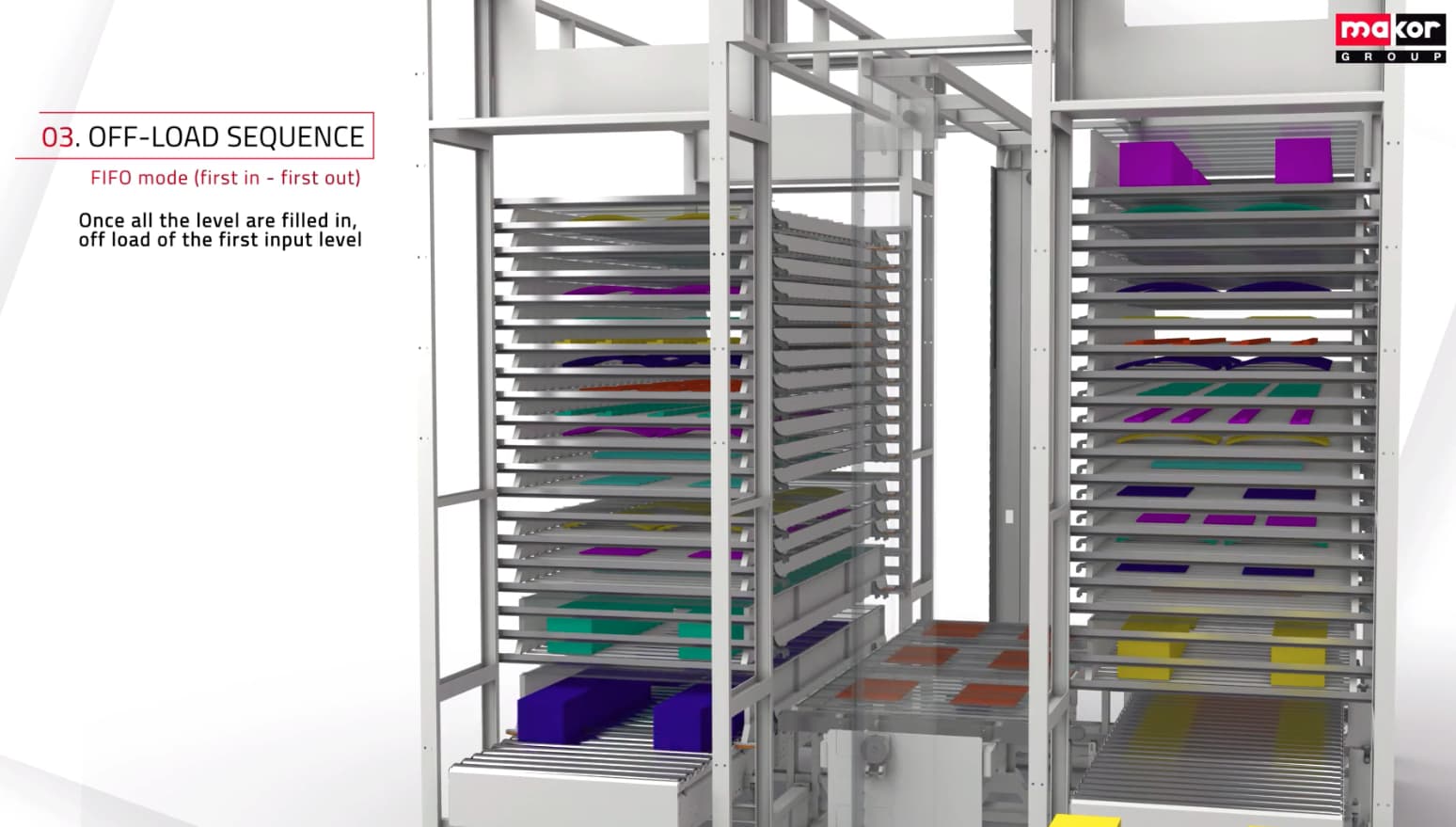

OFF-LOAD MODE

- FIFO (like in the standard oven).

- At set time (every bar-tray is evacuated after the time set).

- Per order (independently for the entrance order, the trays of one order are off-loaded).

- These modes can be realized with any sequence.

MODULARITY

- Possibility to remove/add by hand trays to manage the space dedicated to different thickness.

- Height from 4.2m (20 trays) to 6.5m (50 trays).

- Up to 3 unites in line.

- Tray length 3.6m or 5.5m

AIR FLOWS AND THERMO CONDITIONS

- Air intake from ambient or from one CTA (air treating unit).

- Air warmed by inner coils and available on every tray.

- Management from recipe to Nave, on every tray, laminar air or shill air (optional).

- Manual recirculation of emission air or by humidity control system (optional).