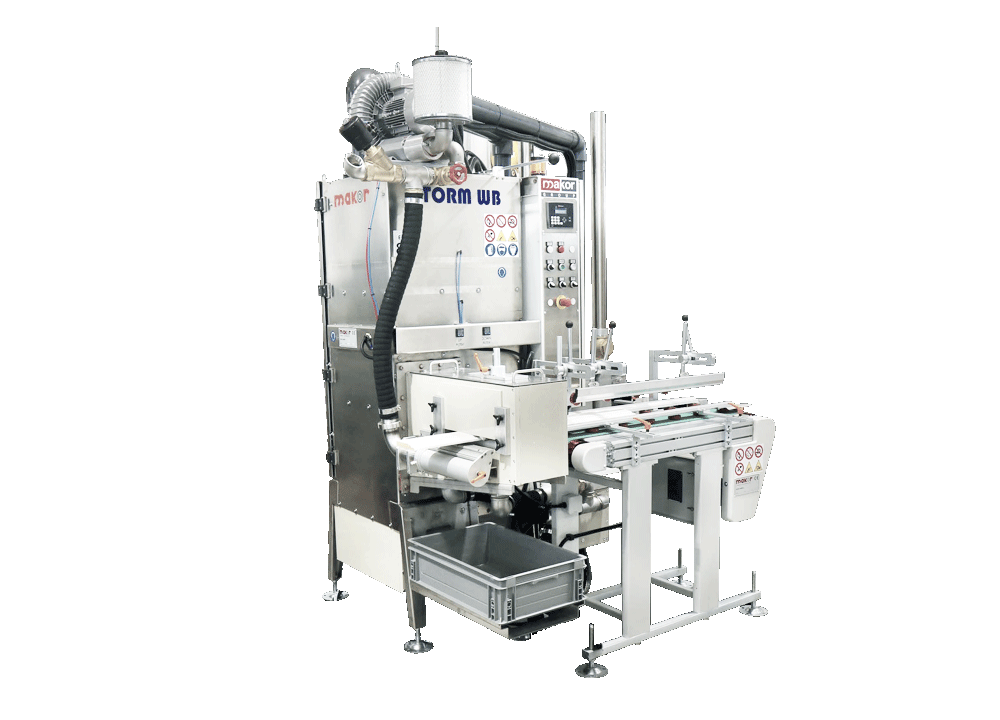

Designed for high production speed or for considerable removal, realized to automatically split, in continuous, finished mouldings produced in double, by cutting a channel on their lower side by means of milling units. The two groups are placed in sequence to allow a first removal, without splitting the moulding, and then the separation operated by the following group. Great stability, easy access. All devices are adjustable, realized with manoeuvre or screws plugs. Belt transmission with feed realized by quite big rubber rollers (in diameter). Impeccable forward feed and piece support. Maximum working safety.

Trasporto a rulli in gomma

High cutting precision

Wide soundproof booth

Easy setup

Available with units to realize glaze-blocking channel

Machine available in various configurations for productions up to 30 m/min